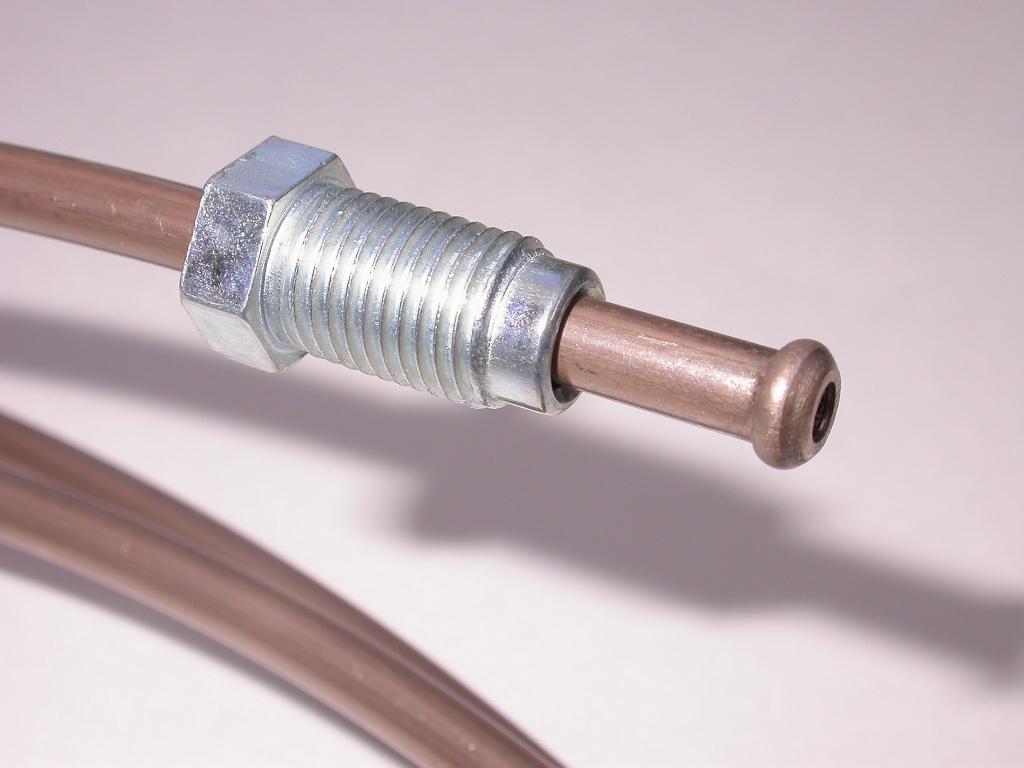

A double flaring tool for brake lines is a device used to shape the ends of metal brake line tubing to properly connect with flared fittings and form strong, leak-resistant joints.

The flaring process involves first stretching the tubing end slightly to form a shallow “single” flare, then using a special cone-shaped die to further shape the flared tubing into a bubble-like “double” flare profile.

Double Flaring vs. Single Flaring

Here are the main differences between double flaring and single flaring for brake lines:

- Double flaring involves flaring the end of the brake line twice – once to flare the metal outward, and a second time to roll that flare back inward slightly. This creates a bead-like appearance.

- Single flaring only flares the end of the brake line outward once. It results in a simpler flare that points straight out from the tube.

- Double flaring is considered stronger and more secure than single flaring. The double-rolled flare helps create a tighter seal when fitting the line to the brake fitting/banjo bolt. This is important for high-pressure brake lines.

- Double flared lines are less likely to leak or pull out of the fitting under heavy braking. The double flare effectively crimps the line in place for maximum strength and sealing.

- Single flaring gets the job done but is not as robust long-term as double flaring. It provides less surface area for the line to grip to the fitting.

- For most street vehicles and normal driving, single flaring is sufficient. But for performance/racing applications with severe braking, double flaring provides superior safety and endurance.

Types of Double Flaring Tools

The double flaring tool for brake lines come in a range of types from basic manual models operated by arm strength up to high-volume hydraulic auto-flaring machines.

Selecting the right flaring tool depends on the production volume, tubing size, shop equipment, and budget. But even the most basic manual double flaring tool can produce professional quality flares if used correctly.

Manual Double Flaring Tools

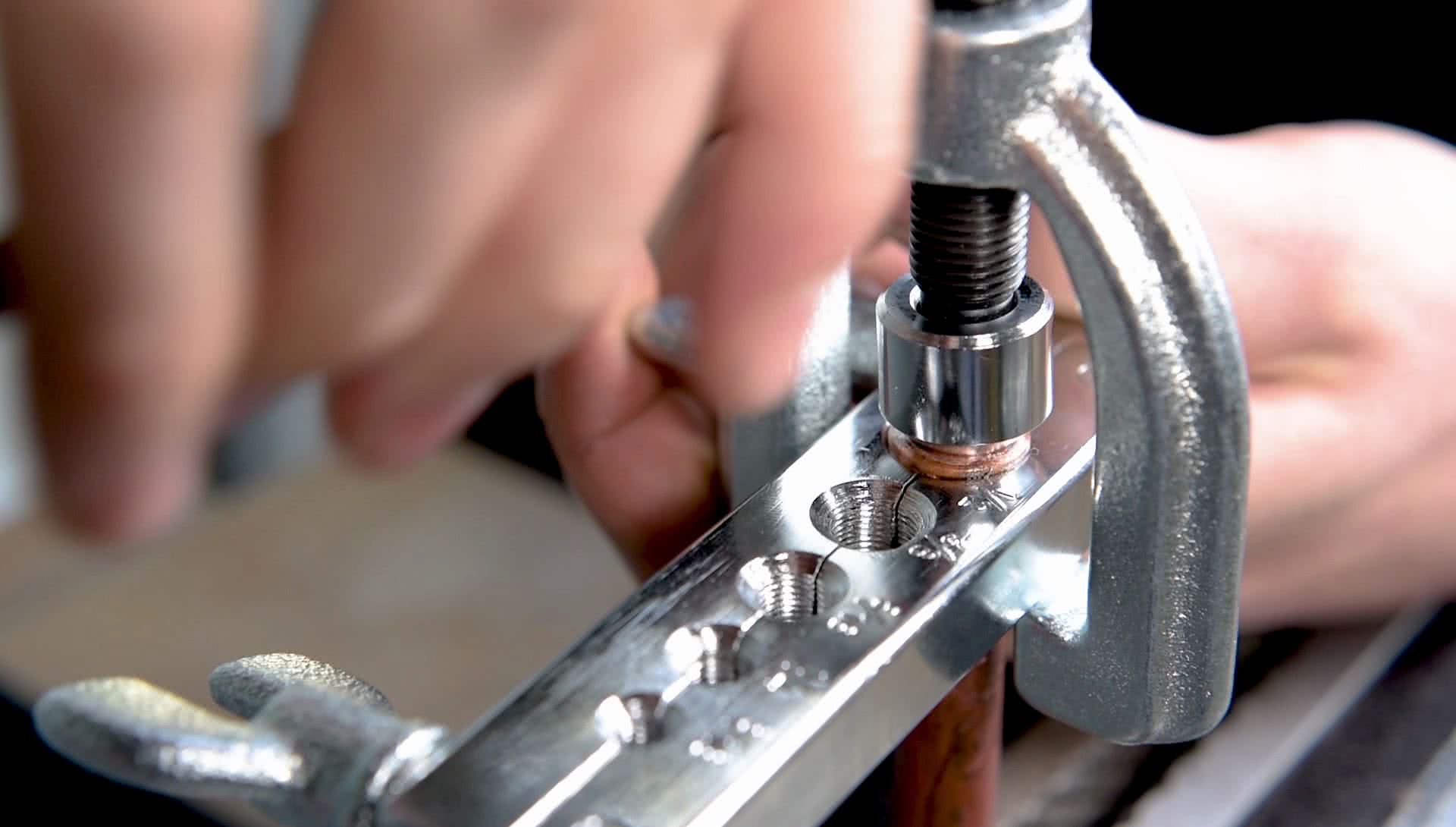

Manual double flaring units provide all the essential functions for DIY brake line fabrication while remaining affordable for home mechanics. Sturdy models like the Eastwood Double Flaring Tool feature solid steel construction with a bench clamp base and quality machined dies.

The key components include a yoke or clamp to firmly hold the tubing, along with precision-milled dies in various sizes to match common metric and standard tubing diameters.

Changeable adapters allow flaring a wide range of tubing from 3mm to over 1/2 inch. The manpower-driven handle pumps up ample leverage pressure to form smooth uniform flares in steel brake line tubing.

Pneumatic Air Flaring Tools

Upgrading to pneumatic flaring systems powered by compressed shop air simplifies heavy-duty brake line fabrication. Air hydraulic models provide the pressure needed for larger tubing sizes with less operator effort.

Controlled air pressure cycling creates precise flaring consistency in high-quantity brake line production environments.

Hydraulic Flaring Presses

Hydraulic pressure flaring systems take commercial-grade production capability to the top level. Standard manual hydraulic pumps allow adjustable pressurization up to 10,000 PSI for heavy wall or large-diameter tubing jobs.

Large-capacity hydraulic reservoirs Lube the flaring process while preventing overheating Failure from repeated operations.

Using a Flaring Tool

Here is how you can use a flaring tool for brake lines:

Selecting Tubing Size and Flaring Adapters

The first step is to ensure you have flaring heads, cones, yokes, and adapters matched to the tubing size being worked with. Many tubing sizes use metric measurements like 3/16″, 4mm, or 5/16″.

Flaring components must match the tubing’s outside diameter. Selecting and properly matching flaring tool components to the brake line tubing is crucial to achieving correct flares. Mixing mismatched hardware can ruin fittings.

Cutting Tubing to Length

Tubing lengths are typically measured, and test-fit between brake line fittings before flaring work begins. The tube ends must be cut squarely using a tube cutter, or fine-toothed saw for best results.

Rough, angled edges will not flare evenly. Deburring is recommended. Cutting tubing precisely prevents internal distortions, which could lead to brake fluid restrictions or leaks.

Reaming the Tube Ends

Most flare tool kits include a reaming blade that removes any interior burrs and beveled cut marks inside freshly cut tubing. Thorough reaming ensures the flaring cone seats evenly for smooth flares. Skip this step, and interior burrs can distort the flare shape.

Rigorously smoothing and remaining tubing interiors allow consistent, even metal flow during flaring.

Lubricating and Mounting Tubes

A light oil lubricates the flaring process, keeping metal surfaces slick and preventing galling or adhesion between the dies and tubing. Avoid heavy grease that could foul brake components later.

Many tools include clamps, vises or yokes that firmly hold the tubing while flaring force is applied. Applying lubricant keeps flaring forces directed properly to shape the tubing instead of distorting it through friction.

Making the First Flare

The initial single flare expands and shapes the tubing circumference to prepare it for the second stage bubble flare. Manual tools require several pumping handle strokes to generate adequate flaring force. Hydraulic models develop higher forces with less effort for easier flaring.

The first flaring phase expands the diameter for the second stage and begins strengthening the tubing through controlled deformation.

Checking the First Flare

Inspect that the first flare profile looks uniform and has expanded the tubing diameter for the second stage flaring.

Re-lubricate and adjust the tubing depth if needed before proceeding. Carefully examining the initial flare confirms proper preparation for the finishing bubble profile.

Conclusion

Working with a double flaring tool for brake lines requires meticulous preparation, precise flaring technique, and quality components for leak-free performance and safe operation.

A double flaring tool forms the properly shaped tubing ends to create secure, reinforced joints containing brake system pressures for the vehicle’s service life. Learning the double flaring process ensures success in automotive brake line fabrication or repair tasks.